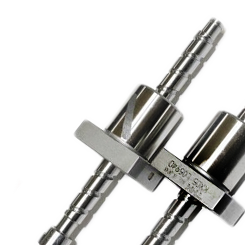

THK丝杆支撑座

- 系列:

- THK

- 型号:THK点击发给客服

THK丝杆支撑座详情概括

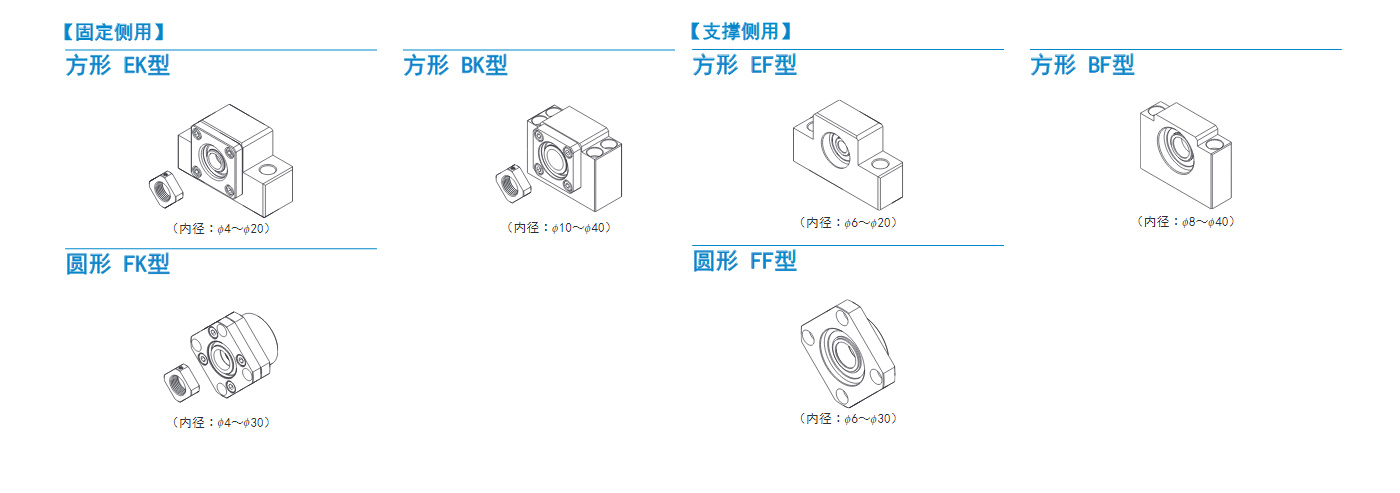

THK丝杆支撑座种类

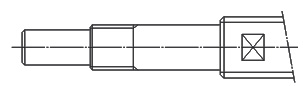

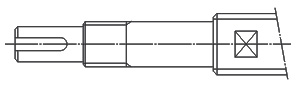

THK丝杆轴端加工种类

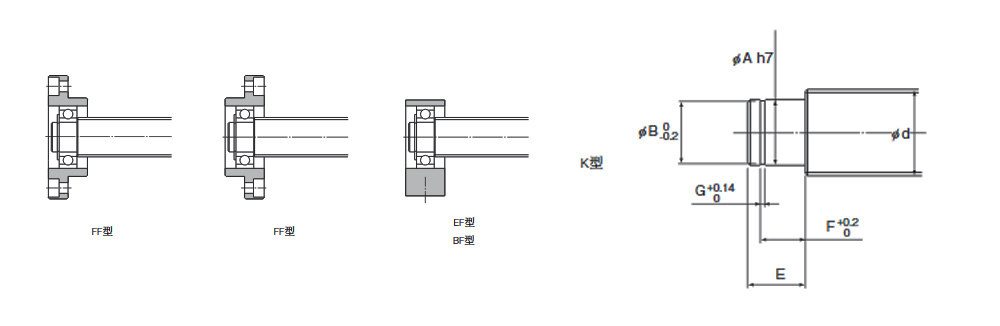

THK已经使丝杠轴端的形状标准化,以便快速估算和制造滚珠丝杠。推荐轴端形状有能直接使用标准支承单元的H、K和J型。| 安装方法 | 轴端形状标记 | 形状 | 适用的支撑座 | |

|---|---|---|---|---|

| 固定 | H、J | H1 |  | FK、EK |

| J1 | BK | |||

| H2 |  | FK、EK | ||

| J2 | BK | |||

| H3 |  | FK、EK | ||

| J3 | BK | |||

| 支撑 | K |  | FF EF BF | |

thK丝杆搭配轴端支撑座型号规格

THK丝杆端形状H型(H1、H2和H3)(用于支承座FK、EK型)

| 丝杆支撑座型号 | 丝杆轴径 d | 轴承部轴外径 A | B | E | F | 公制丝杆螺纹 | 对边宽度 | H2型键槽 | H3型两边加工成平面 | 支撑座位置距离 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FK型 | EK型 | M | S | J | N | H | G N9 | T | P | R | P | FK型 K1 | FK型 K2 | EK型 K3 | |||||

| FK4 | EK4 | 6 | 4 | 3 | 23 | 5 | M4×0.5 | 7 | 4 | 4 | 4 | - | - | - | 2.7 | 4 | 1.5 | 0.5 | 1.5 |

| FK5 | EK5 | 8 | 5 | 4 | 25 | 6 | M5×0.5 | 7 | 5 | 4 | 4 | - | - | - | 3.7 | 5 | 2 | 0.5 | 2 |

| FK6 | EK6 | 10 | 6 | 4 | 30 | 8 | M6×0.75 | 8 | 5 | 4 | 4 | - | - | - | 3.7 | 6 | 3.5 | 0.5 | 3.5 |

| FK8 | EK8 | 12 | 8 | 6 | 35 | 9 | M8×1 | 10 | 8 | 5 | 5 | - | - | - | 5.6 | 7 | 3.5 | 0.5 | 3.5 |

| FK10 | EK10 | 14 | 10 | 8 | 36 | 15 | M10×1 | 11 | 10 | 5 | 7 | 2 | 1.2 | 11 | 7.5 | 11 | 0.5 | -0.5 | -0.5 |

| FK10 | EK10 | 15 | 10 | 8 | 36 | 15 | M10×1 | 11 | 10 | 5 | 7 | 2 | 1.2 | 11 | 7.5 | 11 | 0.5 | -0.5 | -0.5 |

| FK12 | EK12 | 16 | 12 | 10 | 36 | 15 | M12×1 | 11 | 13 | 6 | 8 | 3 | 1.8 | 12 | 9.5 | 12 | 0.5 | -0.5 | -0.5 |

| FK12 | EK12 | 18 | 12 | 10 | 36 | 15 | M12×1 | 11 | 13 | 6 | 8 | 3 | 1.8 | 12 | 9.5 | 12 | 0.5 | -0.5 | -0.5 |

| FK15 | EK15 | 20 | 15 | 12 | 49 | 20 | M15×1 | 13 | 16 | 6 | 9 | 4 | 2.5 | 16 | 11.3 | 16 | 4 | 2 | 5 |

| FK15 | EK15 | 25 | 15 | 12 | 49 | 20 | M15×1 | 13 | 18 | 7 | 10 | 4 | 2.5 | 16 | 11.3 | 16 | 4 | 2 | 5 |

| FK20 | EK20 | 28 | 20 | 17 | 64 | 25 | M20×1 | 17 | 21 | 8 | 11 | 5 | 3 | 21 | 16 | 21 | 1 | -3 | 1 |

| FK20 | EK20 | 30 | 20 | 17 | 64 | 25 | M20×1 | 17 | 24 | 8 | 12 | 5 | 3 | 21 | 16 | 21 | 1 | -3 | 1 |

| FK20 | EK20 | 32 | 20 | 17 | 64 | 25 | M20×1 | 17 | 27 | 8 | 13 | 5 | 3 | 21 | 16 | 21 | 1 | -3 | 1 |

| FK25 | - | 36 | 25 | 20 | 76 | 30 | M25×1.5 | 20 | 27 | 10 | 13 | 6 | 3.5 | 25 | 19 | 25 | 5 | -2 | - |

| FK25 | - | 40 | 30 | 25 | 72 | 38 | M30×1.5 | 25 | 32 | 10 | 15 | 8 | 4 | 32 | 23.5 | 32 | -3 | -9 | - |

THK丝杆端形状J型(J1、J2和J3)(用于支承座BK型)

| 丝杆支撑座型号 | 丝杆轴径 d | 轴承部轴外径 A | B | E | F | 公制丝杆螺纹 | 对边宽度 | J2型键槽 | J3型两边加工成平面 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BK型 | M | S | J | N | H | G N9 | T | P | R | P | |||||

| BK10 | 14 | 10 | 8 | 39 | 15 | M10×1 | 16 | 10 | 5 | 7 | 2 | 1.2 | 11 | 7.5 | 11 |

| BK10 | 15 | 10 | 8 | 39 | 15 | M10×1 | 16 | 10 | 5 | 7 | 2 | 1.2 | 11 | 7.5 | 11 |

| BK12 | 16 | 12 | 10 | 39 | 15 | M12×1 | 14 | 13 | 6 | 8 | 3 | 1.8 | 12 | 9.5 | 12 |

| BK12 | 18 | 12 | 10 | 39 | 15 | M12×1 | 14 | 13 | 6 | 8 | 3 | 1.8 | 12 | 9.5 | 12 |

| BK15 | 20 | 15 | 12 | 40 | 20 | M15×1 | 12 | 16 | 6 | 9 | 4 | 2.5 | 16 | 11.3 | 16 |

| BK17 | 25 | 17 | 15 | 53 | 23 | M17×1 | 17 | 18 | 7 | 10 | 5 | 3 | 21 | 14.3 | 12 |

| BK20 | 28 | 20 | 17 | 53 | 25 | M20×1 | 15 | 21 | 8 | 11 | 5 | 3 | 21 | 16 | 21 |

| BK20 | 30 | 20 | 17 | 53 | 25 | M20×1 | 15 | 24 | 8 | 12 | 5 | 3 | 21 | 16 | 21 |

| BK20 | 32 | 20 | 17 | 53 | 25 | M20×1 | 15 | 27 | 9 | 13 | 5 | 3 | 21 | 16 | 21 |

| BK25 | 36 | 25 | 20 | 65 | 30 | M25×1.5 | 18 | 27 | 10 | 13 | 6 | 3.5 | 25 | 19 | 25 |

| BK30 | 40 | 30 | 25 | 72 | 38 | M30×1.5 | 25 | 32 | 10 | 15 | 8 | 4 | 32 | 23.5 | 32 |

| BK35 | 45 | 35 | 30 | 83 | 45 | M35×1.5 | 28 | 36 | 12 | 15 | 8 | 4 | 40 | 28.5 | 40 |

| BK40 | 50 | 40 | 35 | 98 | 50 | M40×1.5 | 35 | 41 | 14 | 19 | 10 | 5 | 45 | 33 | 45 |

| BK40 | 55 | 40 | 35 | 98 | 50 | M40×1.5 | 35 | 46 | 14 | 20 | 10 | 5 | 45 | 33 | 45 |

THK丝杆端形状K型(用于支承座FF、EF和BF型)

| 丝杆支撑座型号 | 丝杆轴径 d | 轴承部轴外径 A | E | 止动环沟槽 | ||||

|---|---|---|---|---|---|---|---|---|

| FF型 | EF型 | BF型 | B | F | G | |||

| FF6 | EF6 | - | 8 | 6 | 9 | 5.7 | 6.8 | 0.8 |

| - | EF8 | - | 12 | 6 | 9 | 5.7 | 6.8 | 0.8 |

| FF10 | EF10 | BF10 | 14 | 8 | 10 | 7.6 | 7.9 | 0.9 |

| FF10 | EF10 | BF10 | 15 | 8 | 10 | 7.6 | 7.9 | 0.9 |

| FF12 | EF12 | BF12 | 18 | 10 | 11 | 9.6 | 9.15 | 1.15 |

| FF15 | EF15 | BF15 | 20 | 15 | 13 | 14.3 | 10.15 | 1.15 |

| FF15 | EF15 | BF15 | 25 | 15 | 13 | 14.3 | 10.15 | 1.15 |

| - | - | BF17 | 25 | 17 | 16 | 16.2 | 13.15 | 1.15 |

| FF20 | EF20 | BF20 | 28 | 20 | 19(16) | 19 | 15.35(13.35) | 1.35 |

| FF20 | EF20 | BF20 | 30 | 20 | 19(16) | 19 | 15.35(13.35) | 1.35 |

| FF20 | EF20 | BF20 | 32 | 20 | 19(16) | 19 | 15.35(13.35) | 1.35 |

| FF25 | - | BF25 | 36 | 25 | 20 | 23.9 | 16.35 | 1.35 |

| FF30 | - | BF30 | 40 | 30 | 21 | 28.6 | 17.75 | 1.75 |

| - | - | BF35 | 45 | 35 | 22 | 33 | 18.75 | 1.75 |

| - | - | BF40 | 50 | 40 | 23 | 38 | 19.95 | 1.95 |

| - | - | BF40 | 55 | 40 | 23 | 38 | 19.95 | 1.95 |

作者:苏州昇乾达传动

甄选大牌新品推荐

THK丝杆支撑座

考虑到与THK丝杆在刚性上的均衡,使用了高刚性低扭矩的角接触轴承(接触角30°、DF组合)。另外,在EK/FK4、5和6型的微型丝杆支撑座型号中装有专为微型丝杆所开发的微型角接触轴承。

点击进入THK资料 News

- PMI导轨滑块选型流程09-13

- TBI滚珠丝杆精度和轴向间隙09-07

- TBI滑块防尘配件详解09-02

- PMI滑块预压等级详解08-31

THK相关配件选型 Case

- THK丝杆支撑座05-12